Solving Problems & Setting Goals

What is one of the first words that comes from the mouth of a child?

I’m guessing, many of you answered “why?”…..and you’d be spot on. The inquisitive mind of a two-year-old spurs them on to find out all there is to know in their environment. Sadly, in most instances, people grow up and prefer coming up with answers rather than questions. Answers that may or may not be supported by facts. To the annoyance of many around me, I don’t seem to have grown up. I have a habit of asking why?

So, when I came across the 5 WHYs model, I gravitated to it immediately. It gave me permission to bring out my inner child and continue asking “why?”.

5 WHYs

When a problem arises, it is natural to ask the question, “why did this happen?” in an attempt to find a solution and solve the problem. Too frequently we stop there, and end up with an action that deals with a symptom of the issue. This tool goes further. Once the answer to the first question is found, it questions “why?” again in order to get to the original cause. To find the root cause, it is necessary to go to the place where the problem took place and to work with the people who are directly involved to do so. It is a participative tool.

To understand it, here is an example:

- Why did the operator slip?

- Because there was oil on the floor.

- Why was there oil on the floor?

- Because the machine was leaking.

- Why was the machine leaking?

- Because preventive maintenance has not been done.

- Why has preventive maintenance not been done?

- Because the technician in charge is sick and absent.

- Why did not another person replace the technician?

- Because the maintenance range is lost and only he knows how to do it.

The first question gives the information to identify immediate actions to prevent the incident from happening again. The iteration of 5 causes gives the root cause of the problem: the maintenance range is not available so in the absence of the employee in charge of the maintenance of this machine, no one can perform the actions and correctly follow the machine, which resulted in a small oil leak. It is by reaching the root that we make sure we correct the problem and achieve performance!

The iteration of the question “why?” reaches the root cause to correct it.

If you can’t relate to that example, perhaps you can try this one connected to problem solving:

- Why use this tool on a daily basis?

- To characterise my problem and / or identify the root cause.

- Why look for the root cause?

- To effectively deal with my problem.

- Why deal effectively with my problem?

- To do the right thing right away and solve the problem definitively.

- Why do right now?

- To save time.

- Why save time?

- To read blogs and learn new tools / techniques.

In my case, the downside of my “why?” obsession means I can fail to embark on something. As I can’t determine the answer to all my questions to come up with a sound value proposition, I miss out on opportunities.

Talking to someone recently, I realised a possible issue with my thinking. Whilst the 5 WHYs tool has always been my favourite and suits me, it doesn’t necessarily line up with the reasoning of others around me and may not be the best tool for certain circumstances. This particular individual brought me to 2 key realisations:

- whilst the 5 WHYs tool is great for problem solving and root cause analysis, it may not be the best approach when setting goals

- not everyone is a “why” person, in spite of possibly starting off that way as children. People tend to have a thought bias towards one of 5 Ws – Why? Who? What? When? Where?

5Ws

This tool is also based on questions: Who?, What?, Where?, When?, Why?. These different interrogative pronouns provide a deep understanding of the treated subject. Properly defined, the solution or goal becomes clearer to follow. Let’s continue the previous example with this method:

- What are the machines that need a range?

- Who knows the maintenance range?

- What is the status of the maintenance ranges?

- What is their level of update?

- Who is responsible for the maintenance documentation?

- Who could do the maintenance range?

- What is the risk if we lose all ranges?

- Who is the manufacturer of the machine?

- Where are the range cabinets placed?

- When was the last check of the ranges?

- When can we write this range?

- Why did not we notice his absence?

Questions “how?”, “how much?” and “what for?” can complete this questioning.

Conclusion

Both these tools can be used in problem solving, to find the root cause of a problem, or in goal definition. Since they were used in Greece and ancient Rome by philosophers, in their approach of systematic questioning, they have proved their power. Choose the tool based on what suits you, the situation and the others involved.

Thanks to Eponine Pauchard – Performance & Operational Excellence Specialist & Amanda Busstra – Pastor

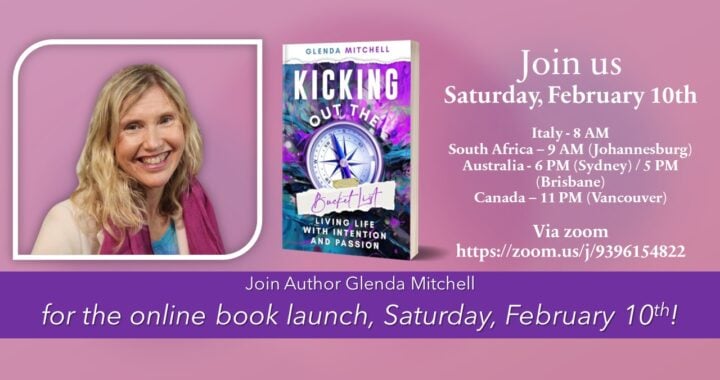

Online Book Launch

Online Book Launch  New Book Release

New Book Release  Book Cover Reveal

Book Cover Reveal  Sneak Preview

Sneak Preview  Imminent Book Release

Imminent Book Release  Lucca 1/2 Marathon

Lucca 1/2 Marathon